Advancing Composite Materials through Molecular Dynamics

Cutting Edge Research and Expertise

- UD-CCM has been at the forefront of molecular dynamics (MD) simulations for over 15 years, modeling the behavior of polymers and composites at the atomistic scale.

- Backed by over 2,300 CPUs from UD’s Caviness cluster and a team of dedicated experts, our research continues to push boundaries in composite materials.

- Proficient in conducting advanced density functional theory calculations using VASP and Quantum ESPRESSO for electronic structure analysis.

- Skilled in both reactive (ReaxFF, AIREBO) and classical (AMBER, PCFF) MD simulations, utilizing state-of-the-art tools such as LAMMPS, OVITO, MAPS, and EMC for advanced materials modeling and analysis.

- MD simulations to provide critical insights into processing conditions affecting fiber/sizing/resin interphase composition and performance under multi-axial loading.

- All predictions are rigorously validated through experimental testing, ensuring accuracy and reliability.

- These high-fidelity models serve as essential inputs for continuum-level simulations, bridging atomistic and macroscale behaviors.

- Published 24 journal articles in high-impact journals, advancing the field of molecular dynamics and composite materials research.

- Presented groundbreaking research at 19 leading conferences organized by the American Society for Composites (ASC) and the Society for the Advancement of Material and Process Engineering (SAMPE), fostering collaborations with academia, industry, and government agencies.

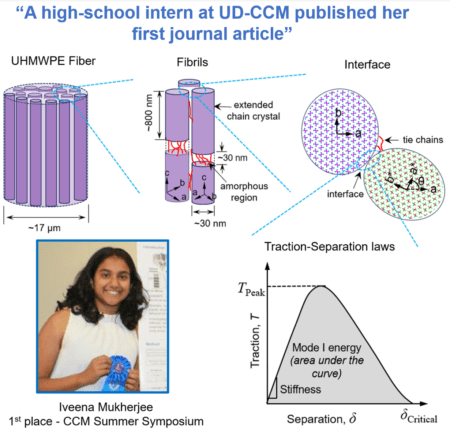

Current Research Focus: UHMWPE Microstructure Optimization

- Investigating the influence of temperature, pressure, and time on UHMWPE composite microstructure.

- Aiming to:

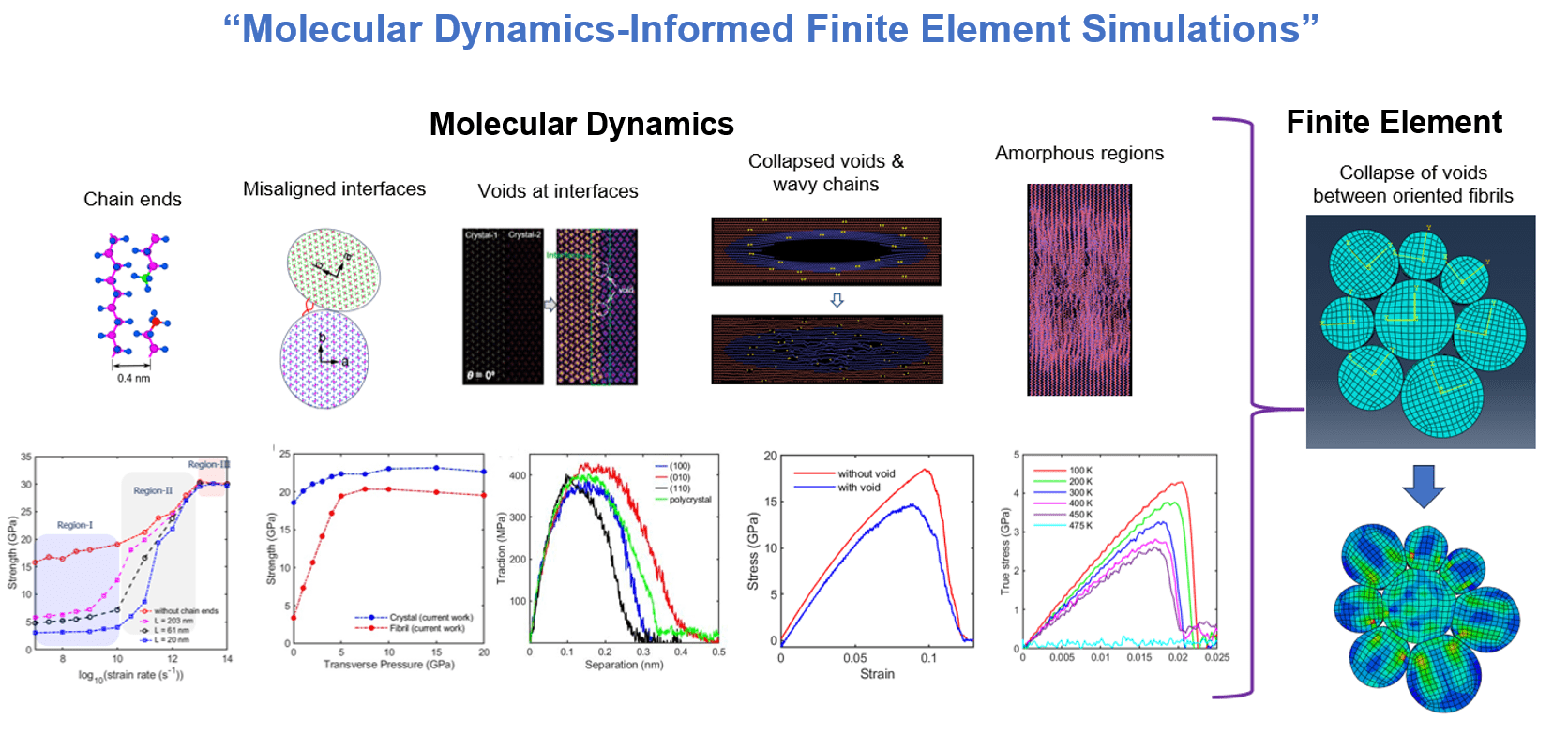

- MD simulations predict:

- MD results are integrated into finite element analysis to provide accurate, scalable composite performance predictions.

– Reduce voids for improved structural integrity.

– Increase fiber volume fraction for enhanced mechanical properties.

– Minimize filament damage to extend composite lifespan.

– 3D stress-strain response and cohesive traction laws for crystalline and amorphous polyethylene.

– The impact of defects, strain rate, molecular weight, transverse pressure from impacts, and temperature effects on progressive failure mechanisms.

Why Partner with Us?

- Pioneering Research: We are at the cutting edge of composite materials science.

- Proven Impact: Our integrated modeling and experimental validation drive real-world innovation.

- Scalability: Our multiscale approach ensures that findings translate from the lab to industrial applications.

- Collaborative Opportunities: We welcome industry partnerships and funding support to expand this groundbreaking research.

CCM is continuously looking for talented interns, graduate students, and postdoctoral researchers to contribute to ongoing and upcoming research programs. Learn more about available opportunities HERE.