Research

UD-CCM’s research philosophy encourages faculty, post-docs, professionals, and students from different science and engineering disciplines to work in a collaborative environment to meet the research needs of our sponsors. Six research thrust areas describe Center interdisciplinary research in composites. Our researchers conduct world-class research in each of these areas but also work in research teams at the interface between these disciplines to design and optimize new materials and processes that deliver performance and affordability.

UD-CCM’s research philosophy encourages faculty, post-docs, professionals, and students from different science and engineering disciplines to work in a collaborative environment to meet the research needs of our sponsors. Six research thrust areas describe Center interdisciplinary research in composites. Our researchers conduct world-class research in each of these areas but also work in research teams at the interface between these disciplines to design and optimize new materials and processes that deliver performance and affordability.

- Materials and Synthesis

Identifying, creating, and tailoring of existing and next generation materials through the control of microstructure and molecular architecture. - Mechanics and Design

Processing-Microstructure-Property relationships to enable design of internal architecture to predict and optimize properties; Multi-scale modeling, Numerical methods, CAD/CAM, Re-engineering, and new software design tools. - Multifunctional Materials

Designing materials to accomplish multiple performance objectives in a single system. Encompassing traditional systems, such as fire-hardened structural composite armor, to newer systems that include blast, sensors and actuators, power harvesting, communications, and electro-optical capabilities. - Performance

State-of-the-art testing and evaluation of a wide range of material, component, and full-scale article properties – mechanical, thermal, electrical, cost, etc. Developing new test procedures and equipment.. - Processing Science

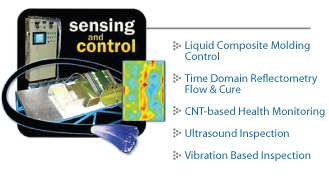

Developing models and simulations in a “virtual manufacturing” environment for process optimization and tool design that leads to improved quality and affordability; Evaluating influence of processing parameters on state of material, Innovate new composite manufacturing processes; Prototyping. - Sensing and Control

Developing on-line sensors and devices for monitoring composites from manufacturing to end-of-life; Develop and validate process control schemes using simulations and manufacturing workcells.