NASA University Leadership Initiative (ULI) – Composite Manufacturing Technologies for Aerospace Performance at Automotive Production Rates

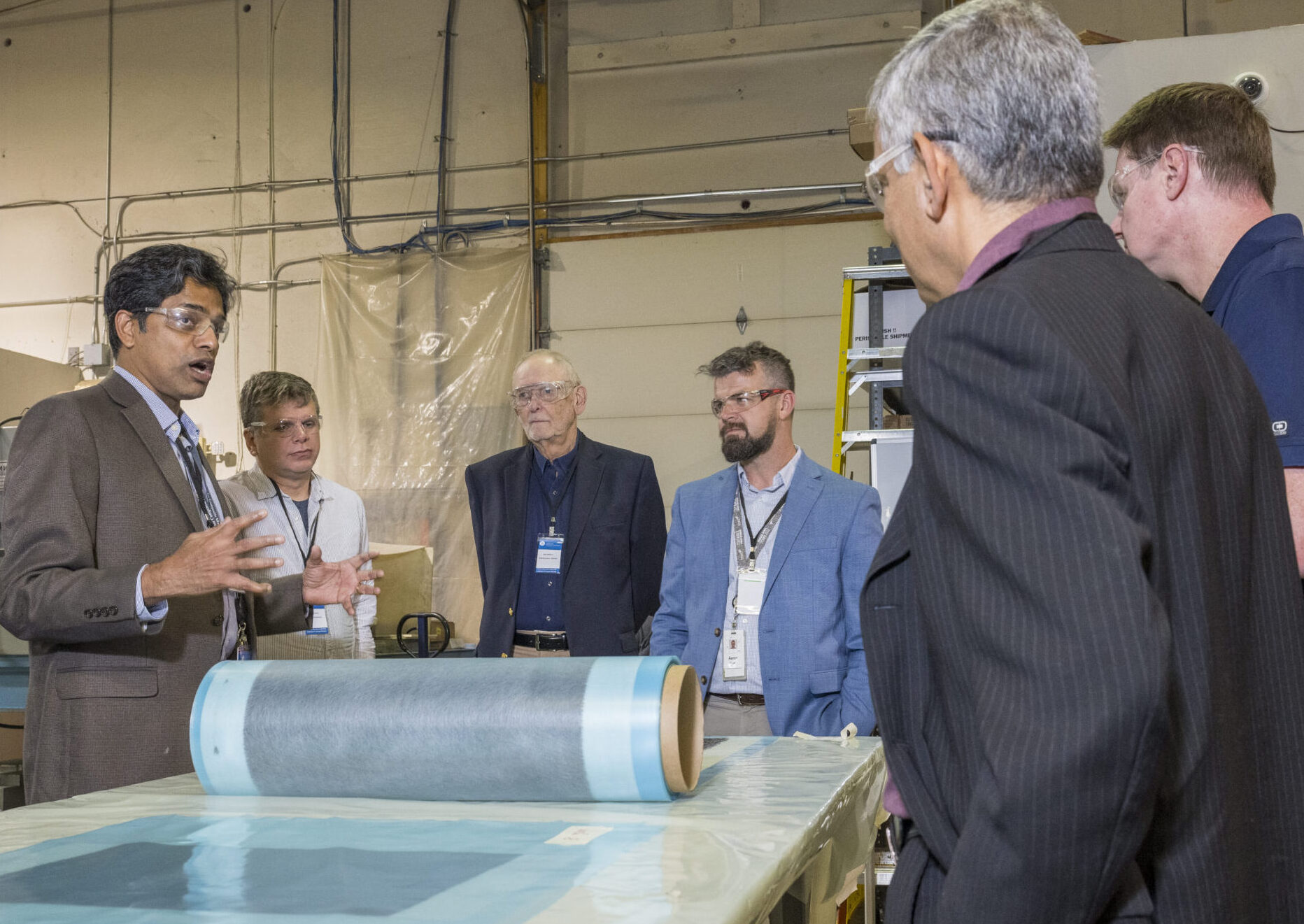

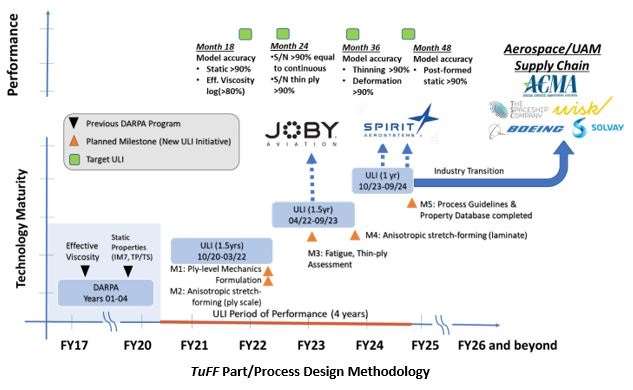

The Technical Challenge is to develop a science-based part/process design methodology for TuFF composites meeting aerospace performance at automotive manufacturing rates, as well as demonstrate at rate manufacturing capability of TuFF complex geometry parts. A combined experimental and modeling approach is leading to TuFF composite part design and manufacturing guidelines for industry transition. Modeling aspects will focus on visualizing and understanding fiber-scale mechanisms of alignment during processing, mechanical loading and rate dependent forming of highly aligned short fiber layers, development of experimentally validated constitutive models, process, and part design.

Anticipated Benefits

Manufacturing research, technology transition and education of students and workforce represent the major goals of our effort. A NASA Roadmap in manufacturing and integrated structures identified UAM technology requirements over a 15-year timeframe with operational prototypes by 2026, and technology scaling by 2031. The goal of our ULI is to address technology barriers in manufacturing of complex geometry composite parts for UAM and commercial air platforms, meeting aerospace performance at automotive-like production rates, and to transition technology to our industrial partners and the US industrial base.

Our highly aligned short fiber material provides a paradigm shift away from expensive and specialized aerospace technology using continuous fiber composites to a new high-performance short fiber composite that can be designed like metals, stamp-formed like metals and reused/recycled like metals.

Student/workforce education represents a core tenet of the project and will provide opportunities for undergraduate interns, graduate research in composites manufacturing and collaborative training/education opportunities with our HBCU and industry partners. Our team also includes OEM/Tier 1 partners, material suppliers and composites industry supply chain. Annual Open Manufacturing Demonstration events are planned with feature-based, non-proprietary geometries to engage the composites eco-system in the US.